Introduction: Understanding the Distinctions

In the realm of manufacturing and machining, the utilization of cutting-edge technology is crucial to meet the demands of modern industries. Two commonly used machines in this field are the 5 axis machine and the traditional milling machine. While both play a vital role in shaping various materials, there are key differences that set them apart. In this article, we will delve into the distinctions between these two machines, exploring their capabilities, applications, and advantages.

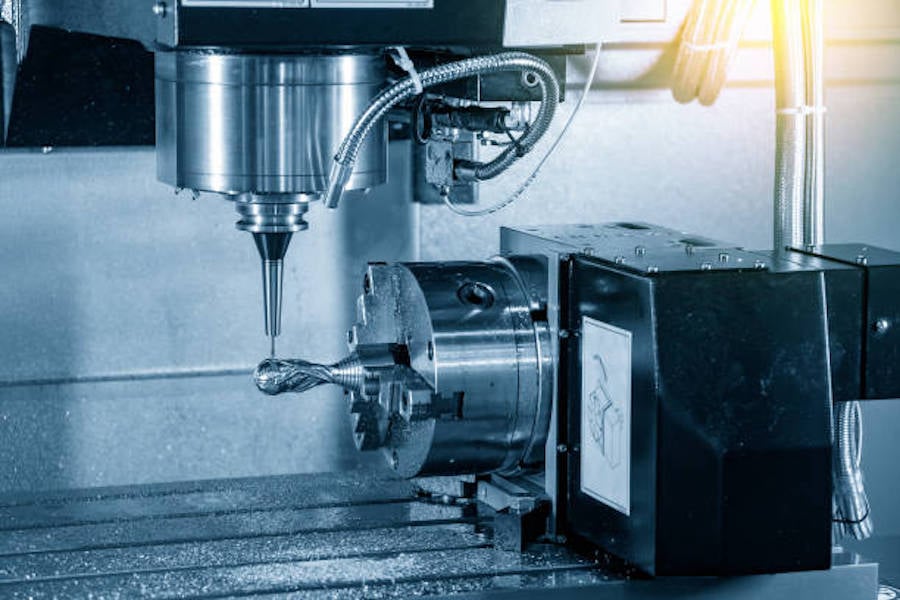

1. Understanding the Basics: What is a 5 Axis Machine?

A 5 axis machine, also known as a 5-axis machining center, is a versatile tool used in the manufacturing industry. Unlike traditional milling machines, which typically operate on three axes (X, Y, and Z), a 5 axis machine can move along two additional rotational axes. This enables the machine to perform complex and intricate operations that would be otherwise impossible to achieve. The ability to maneuver the cutting tool in multiple directions allows for greater precision and flexibility in machining processes.

2. Unveiling the Traditional Milling Machine

The traditional milling machine, on the other hand, operates on the three primary axes: X, Y, and Z. This machine is widely used in various industries and workshops for cutting, drilling, and shaping materials. It employs a rotating cutter to remove material from a workpiece, resulting in the desired shape or form. Traditional milling machines are known for their reliability, simplicity, and cost-effectiveness in performing common machining tasks.

3. Versatility: 5 Axis Machine Takes the Lead

When it comes to versatility, the 5 axis machine undoubtedly takes the lead. With its ability to move along multiple axes, it can execute intricate cuts and contours on complex workpieces. This versatility is especially valuable in industries such as aerospace, automotive, and medical, where intricate designs and precision are paramount. Traditional milling machines, while efficient for simpler tasks, lack the versatility to handle complex geometries and intricate designs.

4. Efficiency and Time-Saving: The Advantage of 5 Axis Machines

Efficiency and time-saving are essential factors in any manufacturing process. The 5 axis machine offers a significant advantage in this regard. With its ability to access multiple sides of a workpiece without repositioning, it reduces the need for multiple setups and clamping. This leads to a significant reduction in machining time and increased productivity. Traditional milling machines, on the other hand, require repositioning and clamping for accessing different sides of a workpiece, resulting in longer machining durations.

5. Precision and Accuracy: 5 Axis Machine's Superiority

Precision and accuracy play a crucial role in machining operations, especially when dealing with intricate or complex designs. The 5 axis machine provides superior precision due to its multi-directional movement capabilities. It can approach a workpiece from various angles and orientations, ensuring precise cuts and contours. Traditional milling machines, while accurate for simpler tasks, may struggle to achieve the same level of precision when dealing with complex geometries.

6. Cost Considerations: Traditional Milling Machine's Advantage

In terms of cost considerations, traditional milling machines have an advantage over 5 axis machines. Traditional milling machines are generally more affordable, making them a cost-effective choice for small to medium-sized businesses or those with simpler machining requirements. 5 axis machines, on the other hand, are more complex and sophisticated, leading to higher upfront costs. However, it is important to weigh the long-term benefits and capabilities offered by a 5 axis machine against the initial investment.

7. Training and Expertise: Complexity of 5 Axis Machines

Operating a 5 axis machine requires a higher level of training and expertise compared to traditional milling machines. The additional rotational axes and the ability to perform complex operations demand a deeper understanding of the machine's capabilities and programming. Traditional milling machines, on the other hand, are relatively simpler to operate and require less specialized training. The complexity of 5 axis machines necessitates skilled operators who are proficient in CAD/CAM software and programming.

8. Applications: Scope of 5 Axis Machines

The diverse range of applications where 5 axis machines excel is a testament to their capabilities. Industries such as aerospace, automotive, medical, and mold-making heavily rely on 5 axis machines for their complex machining requirements. These machines can create intricate components, molds, and prototypes with high precision and accuracy. Traditional milling machines, while limited in their scope, are still widely used in industries that require simpler machining tasks and do not demand the complexity offered by 5 axis machines.

9. Maintenance and Support: Considerations for Longevity

Maintenance and support are crucial factors to consider when investing in any machining equipment. Traditional milling machines have well-established maintenance routines and a vast support network, making it easier to find spare parts and technical assistance. 5 axis machines, being more advanced and sophisticated, may require specialized maintenance and support, which can be more expensive and limited in availability. It is essential to factor in long-term maintenance considerations to ensure the longevity of the chosen machine.

10. Choosing the Right Machine: A Balance of Needs

When deciding between a 5 axis machine and a traditional milling machine, it is crucial to evaluate specific needs and requirements. Consider factors such as the complexity of the machining tasks, precision requirements, available budget, and long-term goals. For industries that demand intricate designs, complex geometries, and high precision, a 5 axis machine proves to be the ideal choice. However, for simpler machining tasks and cost-conscious businesses, a traditional milling machine may suffice. 5 axis machine, traditional milling machine, differences, capabilities, applications, advantages, precision, complexity, cost considerations, training, expertise, maintenance, support, manufacturing, machining What Are the Key Differences Between a 5 Axis Machine and a Traditional Milling Machine?? Discover the key differences between a 5 axis machine and a traditional milling machine. Explore their capabilities, applications, and advantages in the manufacturing and machining industry.