The Evolution of cnc machine.

CNC machines have revolutionized the manufacturing industry, offering unmatched precision, speed, and versatility. From simple tasks to complex operations, these computer-controlled machines have become an integral part of various industries. In this article, we will explore the wide-ranging capabilities of CNC machines and their impact on modern manufacturing processes.

Unleashing the Potential of CNC Machines

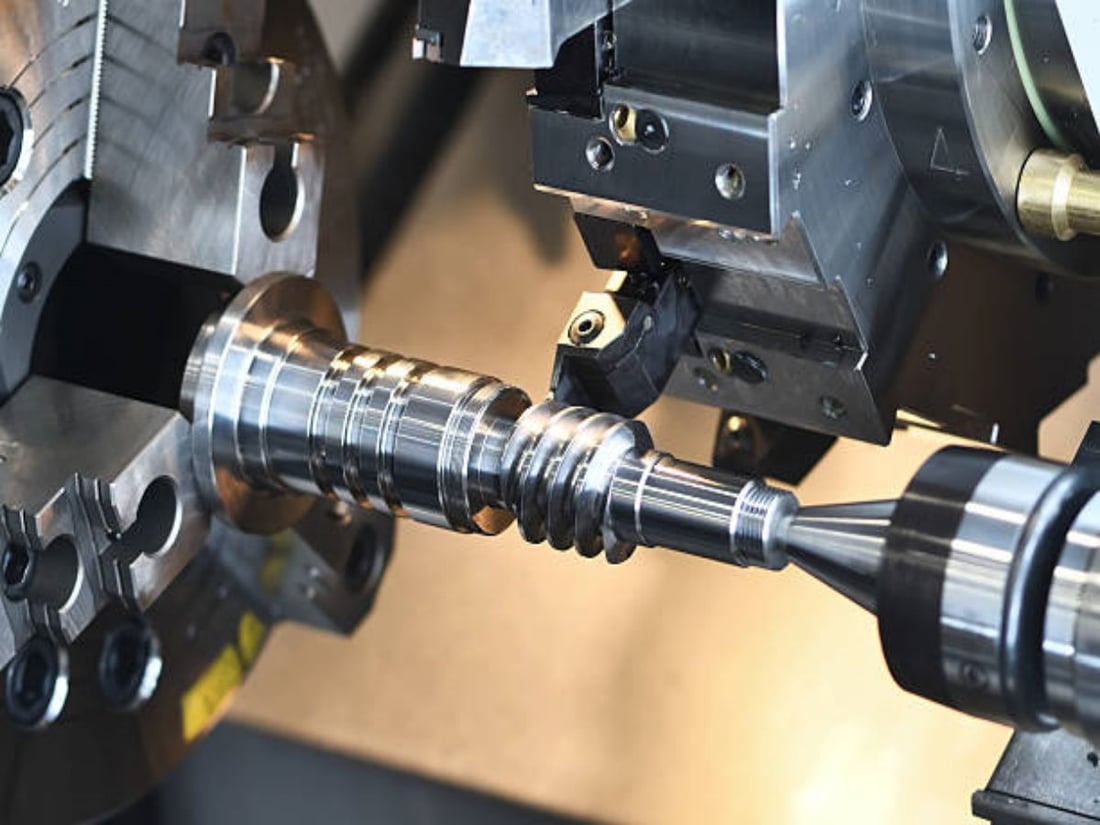

CNC machines, short for Computer Numerical Control machines, are automated tools that utilize computer programming to control their movements and operations. These machines can perform a wide array of tasks, including cutting, drilling, milling, lathing, and engraving. With their exceptional accuracy and repeatability, CNC machines have empowered manufacturers to achieve high levels of productivity and efficiency.

The Advantages of CNC Machines

CNC machines offer numerous advantages over traditional manual machines. Firstly, they eliminate the risk of human error, as the entire process is automated. This ensures consistent and precise results, even when producing complex components. Secondly, CNC machines can operate continuously, reducing production time and increasing output. Additionally, these machines are highly versatile, capable of working with a wide range of materials such as wood, metal, plastic, and composites.

Enhancing Efficiency and Productivity

One of the key benefits of CNC machines is their ability to drastically enhance efficiency and productivity. These machines can work at high speeds while maintaining accuracy, allowing manufacturers to complete projects in a fraction of the time it would take with manual machines. Moreover, CNC machines can work 24/7, leading to increased production capacity and reduced lead times. This enables businesses to meet tight deadlines and handle high-volume orders with ease.

Precision and Accuracy at its Finest

CNC machines are renowned for their exceptional precision and accuracy. By relying on computer programming, these machines can perform intricate tasks with unparalleled detail. Whether it's creating complex shapes or producing intricate designs, CNC machines ensure consistent quality and precise measurements. This level of accuracy is particularly crucial in industries such as aerospace, automotive, and medical, where precision is of utmost importance.

Flexibility and Customization

Another advantage of CNC machines is their flexibility and ability to handle customization. With traditional machines, changing the production process to accommodate different designs or specifications can be time-consuming and expensive. However, CNC machines excel in this aspect, as they can quickly adapt to new instructions by simply modifying the computer program. This allows manufacturers to efficiently produce customized parts and prototypes, catering to the unique needs of their clients.

Streamlining Workflow with Automation

CNC machines automate the production process, minimizing the need for manual intervention. Once the initial setup and programming are complete, these machines can operate independently, freeing up human resources for other tasks. This streamlines the workflow, reduces labor costs, and minimizes the chances of errors or accidents caused by human fatigue. Additionally, automated processes also enhance worker safety and reduce workplace injuries.

Cost Efficiency and Waste Reduction

Implementing CNC machines can lead to significant cost savings for manufacturers. While the initial investment may be higher compared to traditional machines, the long-term benefits outweigh the costs. CNC machines operate with high efficiency, reducing material waste and minimizing production errors. This, in turn, reduces the need for rework and lowers overall production costs. Furthermore, the speed and accuracy of CNC machines enable manufacturers to optimize material usage, further enhancing cost efficiency.

Advanced Capabilities and Complex Operations

CNC machines are equipped with advanced features that enable them to perform complex operations. From multi-axis machining to simultaneous milling, these machines can handle intricate tasks with ease. This opens up new possibilities for manufacturers, allowing them to create intricate designs, complex geometries, and high-precision components. CNC machines also have the capability to integrate additional technologies such as laser cutting, 3D printing, and robotic arms, further expanding their capabilities.

The Future of CNC Machines

As technology continues to advance, CNC machines are poised to become even more powerful and versatile. Integration with artificial intelligence (AI) and machine learning algorithms will further enhance their capabilities, enabling them to adapt, optimize, and self-correct during the manufacturing process. Additionally, the development of more compact and affordable CNC machines will make this technology accessible to a wider range of industries and businesses, driving innovation and reshaping the manufacturing landscape.