The Wonders of Rock Polishing Machines

Rock polishing is a hobby that has gained a lot of popularity over the years. If you are someone who loves collecting stones or just want to make your rocks look more beautiful, a rock polishing machine is a tool you need to have. Here are the Uses of rock polishing machines and the benefits they offer.

The Basics of Rock Polishing

Rock polishing, also known as lapidary, is the art of transforming rough rocks into polished gemstones. This process is done by grinding, sanding and polishing the rocks using a rock polishing machine. The result is a smooth and shiny gemstone that can be used for displays, jewelry making or other decorative purposes.

Creating Beautiful Displays

Rock polishing machines are often used to create beautiful displays of gemstones that can be used in a variety of ways. Some people use polished gemstones as paperweights, while others use them to decorate their homes. With the right combination of stones, you can create stunning displays that will be the envy of your friends and family.

Jewelry Making

Another use of rock polishing machines is in jewelry making. Polished gemstones are often used in jewelry such as necklaces, rings, and bracelets. With a rock polishing machine, you can create your own custom jewelry pieces using your favorite stones. This allows you to add a unique touch to your jewelry designs.

Scientific Research

Rock polishing machines are also used for scientific research. Scientists use polished thin sections of rocks to study the mineral composition of the rocks. Thin sections are made by grinding a rock down to a thickness of a few micrometers and then polishing it to make it transparent. The polished thin section can then be examined under a microscope to determine the mineral composition of the rock.

The Advantages of a Rock Polishing Machine

One of the biggest advantages of using a rock polishing machine is that it saves time. Instead of spending hours grinding and polishing rocks by hand, a rock polishing machine can do the job in a fraction of the time. Polishing machines also produce consistent and even results, which is difficult to achieve by hand.

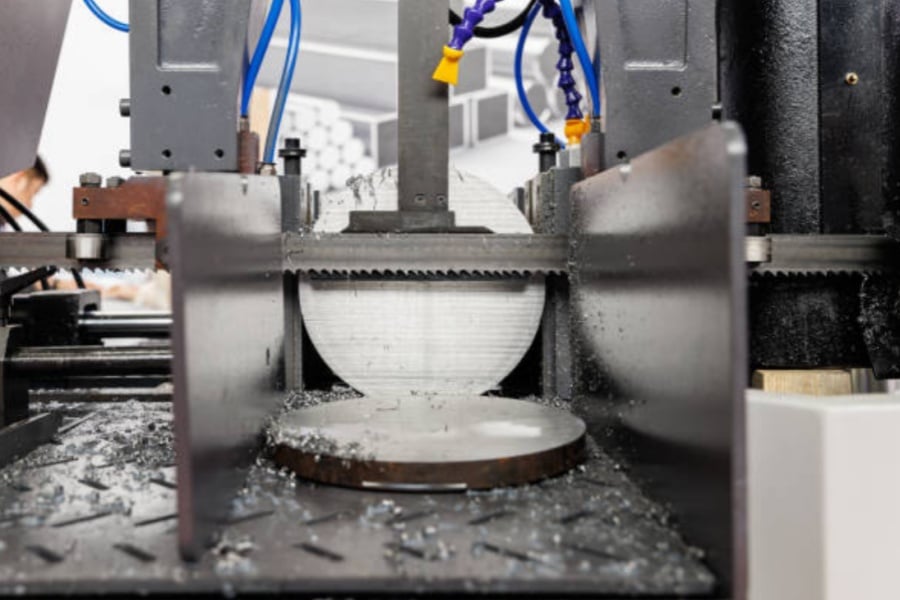

The Different Types of Rock Polishing Machines

There are several types of rock polishing machines on the market, each designed for a specific purpose. The most common types are rotary tumblers, vibratory tumblers, and the flat lap machine. Choosing the right machine depends on the type and size of rocks you want to polish.

The Right Tools for the Job

When using a rock polishing machine, it's important to have the right tools for the job. You'll need a variety of grits of polishing compound, also known as grit, as well as polishing pads or wheels. The grits are used in a sequence, starting with coarse grit and moving to finer grits to achieve a polished finish.

Choosing the Best Rocks to Polish

Not all rocks are suitable for polishing. Some rocks are too soft or too brittle to withstand the grinding and polishing process. It's important to choose rocks that are hard and dense enough to hold up during polishing. Examples of rocks that are commonly polished include agate, jasper, and quartz.

The Safety Precautions to Take

Like any tool, a rock polishing machine can be dangerous if not used properly. It's important to wear personal protective equipment such as gloves, eye protection, and a dust mask when using the machine. The machine should also be used in a well-ventilated area to prevent breathing in dust particles.

Tips for Maintaining Your Rock Polishing Machine

Proper maintenance of your rock polishing machine is essential for its longevity and optimal performance. Regular cleaning of the machine is important to keep it free of debris and to prevent damage to the moving parts. Lubricating the bearings is also important to keep the machine running smoothly.