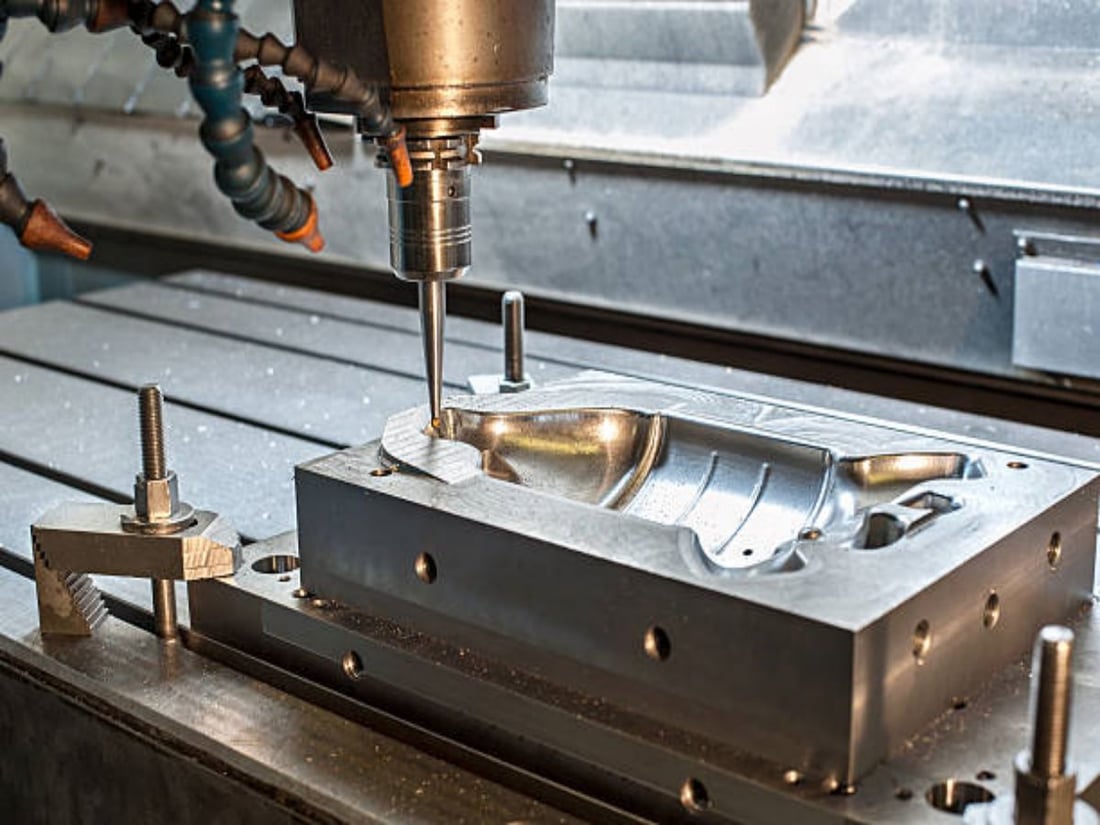

What is a cnc machine mist collector?

A CNC machine mist collector, also known as a CNC machine oil mist collector or a CNC machine mist extractor, is a device specifically designed to remove harmful mist, smoke, and fine particles generated during machining processes. These collectors play a crucial role in maintaining a healthy and efficient workplace environment by reducing air pollution, preventing respiratory issues, and improving the overall quality of the air.

Benefits of Using CNC Machine Mist Collectors

Using a CNC machine mist collector offers numerous benefits for both the operators and the CNC machines themselves. Let's explore some of the key advantages:

1. Health and Safety

One of the primary reasons for using a mist collector is to protect the health and safety of the operators. CNC machines often produce hazardous airborne particles, such as oil mist, coolant mist, and metal dust, which can lead to respiratory problems and other health issues. By removing these contaminants from the air, mist collectors help create a safer working environment.

2. Improved Air Quality

CNC machine mist collectors effectively remove oil and coolant mist, smoke, and fine particles from the air, resulting in improved air quality. This not only benefits the operators but also helps maintain the cleanliness of the surrounding area and other equipment in the workshop. Cleaner air also contributes to a more pleasant working environment and reduces the risk of machine malfunctions caused by dust accumulation.

3. Extended Tool Life

When mist generated during CNC machining is not properly extracted, it can settle on tools and components, leading to premature wear and corrosion. By capturing the mist at its source, mist collectors prevent the mist from settling on the tools, significantly extending their lifespan and reducing maintenance costs.

4. Enhanced Machine Performance

Mist collectors contribute to the overall performance and efficiency of CNC machines. By removing mist and smoke, these collectors help maintain stable machining conditions, prevent heat buildup, and reduce the risk of overheating. This enables CNC machines to operate at their optimal level, resulting in improved accuracy, productivity, and reduced downtime.

5. Environmental Responsibility

Using mist collectors demonstrates a commitment to environmental responsibility. By capturing and filtering mist and smoke, these devices prevent the release of harmful particles into the atmosphere, helping to reduce the overall environmental impact of machining processes.

Choosing the Right CNC Machine Mist Collector

When selecting a CNC machine mist collector, several factors should be considered:

1. Airflow Capacity

The airflow capacity of the mist collector should match the requirements of the CNC machine and the machining process. It is essential to ensure that the collector can effectively capture and remove mist and smoke generated during operation.

2. Filtration Efficiency

The filtration efficiency of the mist collector is crucial in ensuring that the captured mist and smoke are effectively removed from the air. High-quality filters with a high filtration efficiency should be used to ensure optimal performance.

3. Maintenance and Filter Replacement

Consider the ease of maintenance and filter replacement when choosing a mist collector. Regular maintenance and filter replacements are necessary to keep the collector functioning effectively. Select a mist collector that offers convenient access for maintenance tasks.

4. Noise Level

Some mist collectors can generate noise during operation, which can be disruptive in a workshop environment. It is important to choose a mist collector with a noise level that meets the requirements of the workplace and minimizes disturbance to the operators.

5. Size and Design

The size and design of the mist collector should be suitable for the available space in the workshop. Consider factors such as installation options, portability, and the ability to integrate the collector with the CNC machine.