Introduction

CNC machines and 3D printers are two remarkable technologies that have revolutionized various industries. While CNC machines enable precise and automated manufacturing processes, 3D printers allow for the creation of complex three-dimensional objects. In this article, we will explore the advantages and applications of both CNC machines and 3D printers, highlighting their unique features and capabilities.

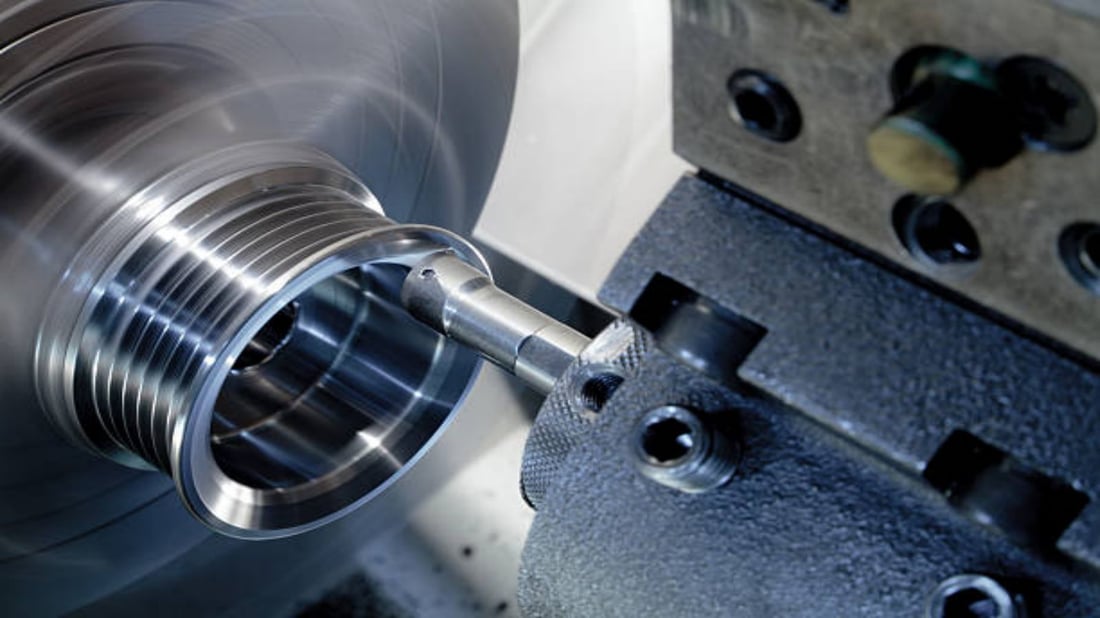

The Power of CNC Machines

CNC machines, short for Computer Numerical Control machines, are automated tools that utilize computer programming to control their operations. These machines are widely used in industries such as manufacturing, aerospace, automotive, and prototyping. The key advantages of CNC machines include:

Precision and Accuracy

One of the primary advantages of CNC machines is their ability to produce highly precise and accurate parts. By utilizing computer-aided design (CAD) software, engineers can create detailed 3D models that are then translated into machine code. This code controls the movements of the CNC machine, ensuring that each cut, drill, or engraving is executed with exceptional precision.

Efficiency and Productivity

CNC machines offer unparalleled efficiency and productivity compared to traditional manual methods. Once programmed, these machines can work continuously, 24/7, without the need for human intervention. This maximizes production output and reduces labor costs, making CNC machines a cost-effective solution for large-scale manufacturing.

Flexibility and Customization

With CNC machines, customization and flexibility are easily achievable. The ability to quickly reprogram the machine allows for the production of different parts without the need for extensive setup changes. This flexibility is particularly advantageous in industries where batch sizes and product designs change frequently.

Unlocking the Potential of 3D Printing

3D printing, also known as additive manufacturing, is a process that transforms digital designs into physical objects by building them layer by layer. This technology has gained significant popularity in recent years and offers numerous benefits in various fields. Let's explore some of the advantages and applications of 3D printing:

Prototyping and Rapid Iteration

3D printing has revolutionized the prototyping process by allowing designers and engineers to quickly create physical models. This enables rapid iteration and testing, resulting in faster product development cycles. By eliminating the need for costly and time-consuming tooling, 3D printing significantly reduces prototyping costs and accelerates time to market.

Complex Geometry and Design Freedom

One of the most notable advantages of 3D printing is the ability to create objects with complex geometries that would be challenging or impossible to produce using traditional manufacturing methods. This opens up new design possibilities and allows for the creation of intricate and lightweight structures, which can be advantageous in industries such as aerospace and healthcare.

Customization and Personalization

3D printing enables customization and personalization on a scale never seen before. By utilizing digital designs, individuals can create unique and tailored products to meet their specific needs. From custom-fit medical implants to personalized consumer goods, 3D printing empowers individuals to have greater control over the products they use.

Applications and Synergy

Both CNC machines and 3D printers find applications in a wide range of industries. While CNC machines excel in large-scale manufacturing processes, 3D printers are best suited for prototyping, low-volume production, and customization. However, there are instances where these technologies work together to create synergistic solutions:

Hybrid Manufacturing

Hybrid manufacturing combines the strengths of CNC machines and 3D printers to create complex parts with high precision. The process involves using a CNC machine to perform initial machining operations on a part, followed by 3D printing to add intricate features or fine details. This hybrid approach allows for the production of parts that leverage the benefits of both technologies.

Jigs, Fixtures, and Tooling

Both CNC machines and 3D printers play a crucial role in the production of jigs, fixtures, and tooling. CNC machines excel in producing durable and high-precision tooling, while 3D printers can quickly create complex and custom-designed jigs and fixtures. The combination of these technologies ensures efficient and accurate manufacturing processes.

Education and Research

Both CNC machines and 3D printers have become essential tools in educational institutions and research facilities. They provide students and researchers with hands-on experience and the ability to turn ideas into physical objects. These technologies foster creativity, innovation, and problem-solving skills, preparing future generations for careers in advanced manufacturing.