The Power of micro cnc Technology

The manufacturing industry has undergone a transformation of epic proportions in recent years. Gone are the days of relying on manual labor to produce mass quantities of products. Instead, modern-day manufacturers are employing sophisticated automated systems to streamline their production processes, reduce errors and increase overall efficiency. One such technology that is making a big impact in the industry is micro CNC, which offers a multitude of benefits to businesses of all sizes. In this article, we will explore the benefits of this technology and how it is revolutionizing manufacturing.

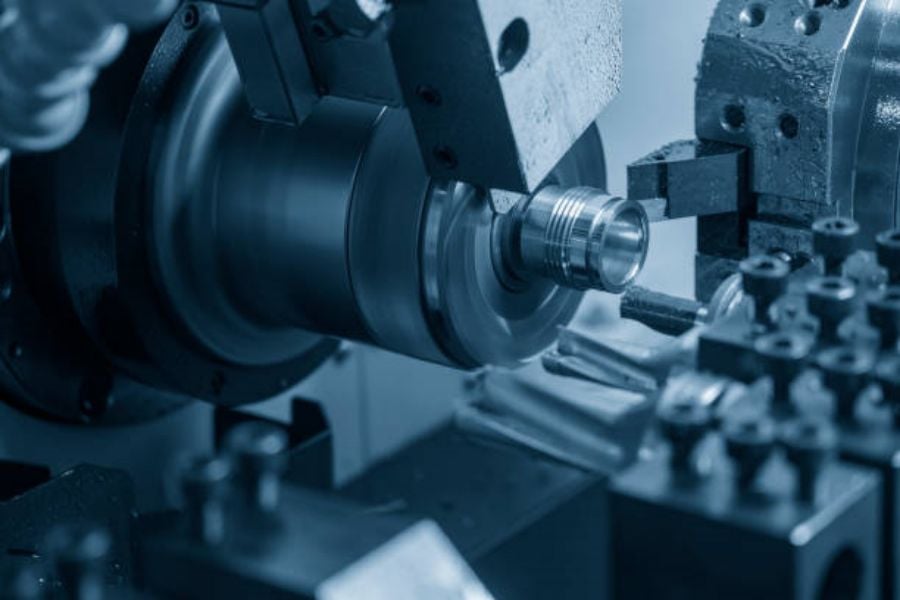

What is Micro CNC?

Micro CNC is a computer numerical controlled (CNC) machine that is capable of making precise cuts in materials at a microscopic level. These machines offer unmatched precision and accuracy in material cutting, with tolerances as small as 0.0001 inches. Micro CNC machines are commonly used in industries such as medical device manufacturing, aerospace engineering, and electronics production.

Benefits of Micro CNC in Manufacturing

1. Increased Efficiency

One of the primary benefits of micro CNC is its ability to increase efficiency in manufacturing processes. By automating the cutting process, micro CNC machines can produce high volumes of products with consistent precision and accuracy, reducing the need for manual intervention and minimizing errors.

2. Reduced Waste

Micro CNC machines are designed to optimize material usage, reducing waste and ultimately saving money for manufacturers. These machines can cut complex shapes and designs with minimal scrap material, ensuring that as much of the raw material is used as possible.

3. Improved Quality

Micro CNC machines produce products with unparalleled precision and accuracy, resulting in products that are of consistently high quality. With less room for error, manufacturers can produce parts that meet requirements and comply with regulatory standards more easily.

4. Cost Savings

Implementing micro CNC technology can result in significant cost savings for manufacturers. With automated processes and reduced waste, manufacturers can produce more products with less resources. Additionally, the high level of precision and accuracy can lower the need for reworks and repairs, ultimately lowering costs and boosting profitability.

5. Streamlined Production

Micro CNC machines can be programmed to streamline production processes, reducing the need for human intervention and increasing speed and output. These machines are often used in industries where high-volume production is required, such as electronics manufacturing, where tight deadlines and large orders are common.

6. Increased Innovation

Micro CNC technology has opened up new possibilities for innovation in manufacturing. With the ability to produce complex shapes and designs with precision and consistency, manufacturers can create products that were previously impossible to produce. This technology has enabled advancements in industries such as aerospace and medical devices, where precision and quality are critically important.

7. Greater Flexibility

Micro CNC machines offer a high degree of flexibility to manufacturers, allowing them to cut a variety of materials with ease. These machines can be programmed to cut materials of varying thickness and hardness, making them adaptable to a wide range of manufacturing needs.

8. Improved Safety

By automating the cutting process, micro CNC machines reduce the need for manual labor and ultimately improve safety in the workplace. These machines can operate for extended periods without requiring breaks or rest, reducing the risk of accidents and injuries associated with manual labor.

9. Competitive Edge

Implementing micro CNC technology can give businesses a competitive edge in the market. With the ability to produce high-quality products at a faster rate and lower cost, manufacturers can offer competitive pricing and shorter lead times, attracting more customers and driving business growth.

10. Future-Proofing Manufacturing

Investing in micro CNC technology is a smart move for businesses looking to future-proof their manufacturing processes. As the industry continues to evolve and demand for high-precision products grows, businesses that embrace these technologies will be better equipped to meet customer needs and stay ahead of the competition.

Conclusion

Micro CNC technology is revolutionizing manufacturing, offering a range of benefits including increased efficiency, improved quality, cost savings, and much more. With the ability to produce high-precision products at a faster rate and lower cost, it's a smart investment for businesses looking to stay competitive in today's market.