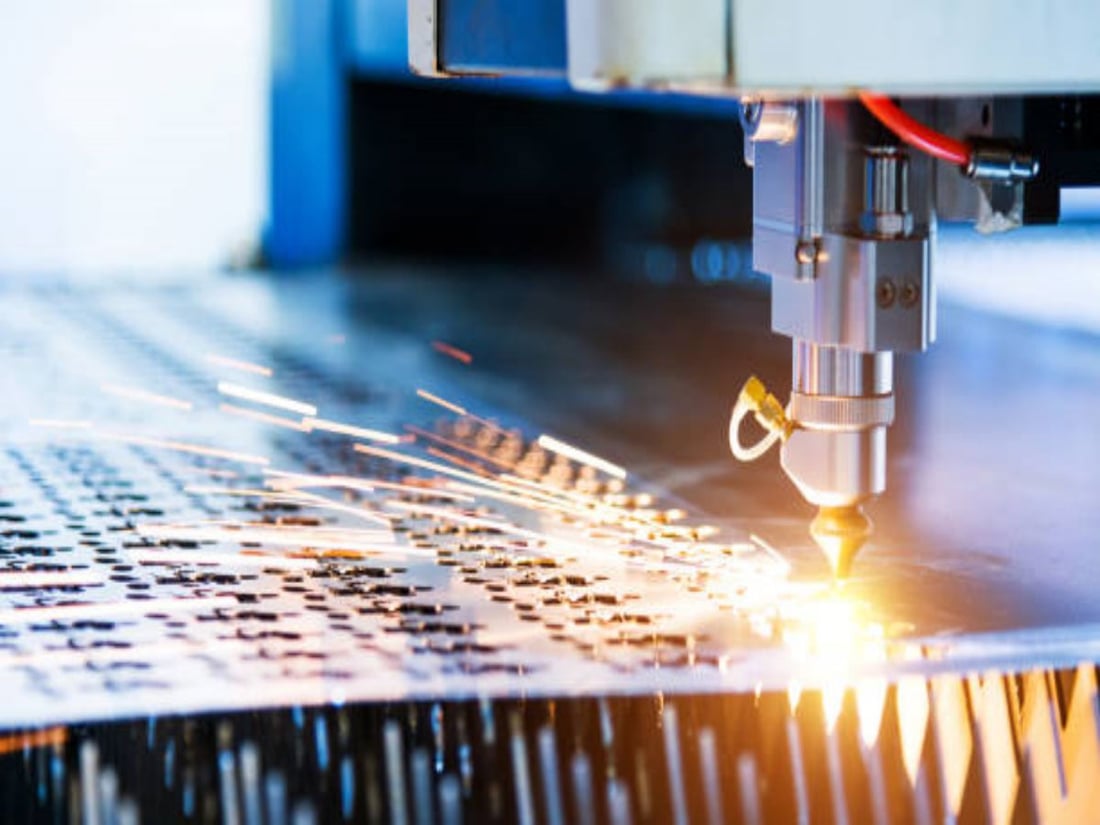

The Advancements in Precision Manufacturing with gantry 5 axis cnc machines

Gantry 5 axis CNC machines have emerged as a game-changer in precision manufacturing. With their ability to perform complex machining tasks with unparalleled accuracy, these machines have revolutionized various industries. In this article, we will explore the various aspects of gantry 5 axis CNC machines and their impact on modern manufacturing processes.

The Basics of Gantry 5 Axis CNC Machines

Gantry 5 axis CNC machines are advanced machining tools that utilize computer numerical control (CNC) technology to control the movement of cutting tools in five different axes. Unlike traditional CNC machines, which are limited to three axes (X, Y, and Z), gantry 5 axis CNC machines offer two additional axes of rotation and tilt, allowing for a greater range of motion and more complex machining operations.

The Benefits of Gantry 5 Axis CNC Machines

Gantry 5 axis CNC machines offer numerous advantages over their 3-axis counterparts. Firstly, the additional axes of rotation and tilt enable these machines to create intricate and highly precise geometric shapes, reducing the need for multiple setups and minimizing machining time. This increased efficiency translates into cost savings and faster production cycles.

Applications of Gantry 5 Axis CNC Machines

The versatility of gantry 5 axis CNC machines makes them suitable for a wide range of applications. They are commonly used in aerospace and automotive industries for manufacturing complex components such as turbine blades and engine parts. Additionally, these machines find applications in the medical field for producing intricate surgical instruments and implants. The tooling and mold-making industry also benefits from the capabilities of gantry 5 axis CNC machines.

The Importance of Precision in Manufacturing

Precision is a critical aspect of modern manufacturing, and gantry 5 axis CNC machines play a pivotal role in achieving the required accuracy. The ability to machine complex shapes with tight tolerances ensures that the end products meet the desired specifications. This level of precision is crucial in industries where safety and reliability are paramount, such as aerospace and medical manufacturing.

Key Features of Gantry 5 Axis CNC Machines

Gantry 5 axis CNC machines come equipped with several key features that enhance their performance and versatility. One of the notable features is the rotary table, which enables the rotation of the workpiece along multiple axes. This feature allows for continuous machining without the need for repositioning, resulting in reduced setup time and improved accuracy.

The Role of Software in Gantry 5 Axis CNC Machines

Software plays a crucial role in the operation of gantry 5 axis CNC machines. Advanced CAD/CAM software enables the creation of intricate 3D models, which can be directly translated into machine instructions. The software also provides simulation capabilities, allowing operators to visualize the machining process and identify potential issues before actual production begins.

Challenges in Implementing Gantry 5 Axis CNC Machines

While gantry 5 axis CNC machines offer numerous benefits, their implementation can present certain challenges. The complexity of programming and operating these machines requires skilled personnel with a deep understanding of both CNC technology and the specific application. Additionally, the high initial cost of gantry 5 axis CNC machines may pose a barrier for some manufacturers.

Future Trends in Gantry 5 Axis CNC Machines

The field of gantry 5 axis CNC machines is constantly evolving, with ongoing research and development to further enhance their capabilities. One emerging trend is the integration of artificial intelligence (AI) algorithms to optimize machining processes and improve efficiency. Additionally, advancements in materials and cutting tool technologies continue to push the boundaries of what can be achieved with gantry 5 axis CNC machines.

The Bottom Line

Gantry 5 axis CNC machines have transformed precision manufacturing by enabling the production of complex and highly accurate components. Their ability to perform intricate machining operations with minimal setup time and maximum efficiency makes them invaluable in various industries. As technology continues to advance, gantry 5 axis CNC machines will likely play an even more significant role in shaping the future of manufacturing.