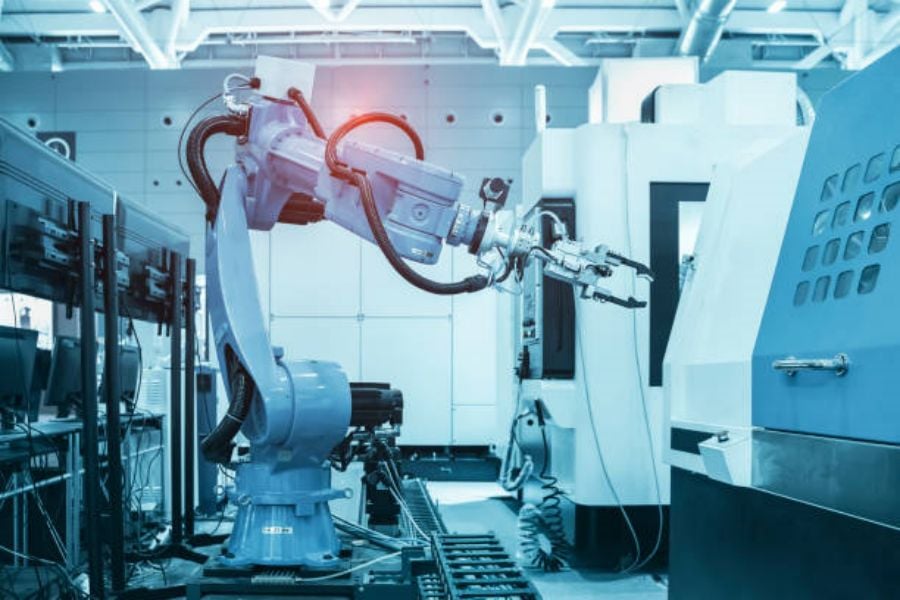

The Rise of fiber laser machines in Industrial Applications

In recent years, fiber laser machines have gained significant popularity in the field of laser technology. These cutting-edge machines are revolutionizing various industrial applications, from metal cutting and welding to engraving and marking. With their exceptional precision, speed, and efficiency, fiber laser machines are becoming the go-to choice for businesses seeking high-quality and cost-effective solutions. In this article, we will explore the different aspects of fiber laser machines and their impact on various industries.

Understanding the Technology Behind Fiber Laser Machines

Fiber laser machines operate based on the concept of stimulated emission. Unlike traditional CO2 lasers that use gas as the medium, fiber lasers rely on optical fibers doped with rare-earth elements such as erbium, ytterbium, or neodymium. These doped fibers act as the amplifying medium, allowing for the generation of a concentrated laser beam with outstanding beam quality and power stability. The compact design and solid-state nature of fiber lasers make them highly reliable and suitable for a wide range of applications.

The Advantages of Fiber Laser Machines

Fiber laser machines offer numerous advantages over conventional laser technologies. One of the key benefits is their high efficiency, with fiber lasers converting over 30% of electrical energy into usable laser power. This efficiency not only reduces energy consumption but also minimizes operating costs for businesses. Additionally, fiber lasers provide superior beam quality, resulting in cleaner and more precise cuts, welds, and engravings. They also have a longer operational lifespan, requiring minimal maintenance and downtime.

Applications of Fiber Laser Machines in Metal Cutting

One of the primary applications of fiber laser machines is metal cutting. Whether it's stainless steel, aluminum, or copper, these machines can effortlessly slice through various metals with exceptional speed and precision. The ability to produce intricate and complex designs makes fiber laser machines ideal for cutting thin sheets as well as thick plates. The high-power density of the laser beam enables clean and narrow cuts, minimizing material waste and post-processing requirements.

Fiber Laser Machines in Welding and Joining Processes

Another significant application of fiber laser machines is in welding and joining processes. The high energy concentration and small spot size of fiber lasers allow for precise and deep weld penetration, resulting in strong and reliable welds. Whether it's spot welding, seam welding, or remote welding, fiber laser machines provide excellent control and repeatability. They also offer enhanced flexibility by enabling multi-axis welding and simultaneous welding of different materials.

Engraving and Marking with Fiber Laser Machines

Fiber laser machines are widely used for engraving and marking applications. Whether it's logos, serial numbers, barcodes, or intricate designs, these machines can etch permanent and high-contrast marks on a variety of materials, including metals, plastics, and ceramics. The precise control and fast processing speed of fiber lasers make them ideal for high-volume production lines, where quick and accurate marking is essential. Fiber laser marking is also resistant to fading, ensuring long-lasting and durable markings.

Fiber Laser Machines and the Medical Industry

The medical industry is also benefiting from the advancements in fiber laser technology. Fiber laser machines are revolutionizing medical device manufacturing, enabling the production of intricate and miniaturized components. These machines are used for cutting stents, surgical tools, and implants with high precision and minimal thermal damage. Fiber lasers are also employed in laser ablation, a non-invasive procedure for removing unwanted tissues or treating various medical conditions.

Fiber Laser Machines in the Automotive Sector

The automotive sector is another industry that has embraced fiber laser machines. These machines are used for cutting and welding automotive components, such as chassis, body panels, and exhaust systems. The high cutting speed and accuracy of fiber lasers enable efficient production and assembly of automotive parts. Additionally, fiber lasers are employed in the production of automotive sensors, ensuring reliable and precise measurement and control systems.

Future Developments and Innovations in Fiber Laser Machines

The future of fiber laser machines looks promising, with ongoing research and development focusing on enhancing their capabilities. One area of innovation is the continuous increase in laser power, allowing for faster cutting and welding speeds. Another area of interest is the development of hybrid laser systems that combine fiber lasers with other laser technologies to expand their range of applications. Furthermore, advancements in beam shaping and delivery systems are enabling more complex and tailored laser processes.

Choosing the Right Fiber Laser Machine for Your Business

When selecting a fiber laser machine for your business, it's essential to consider various factors, such as power requirements, working area size, and desired applications. Different models and configurations are available to suit specific needs, whether you require a compact desktop machine or a large-scale industrial system. It's also crucial to choose a reputable manufacturer or supplier who can provide reliable customer support, training, and maintenance services.

The Future is Bright for Fiber Laser Machines

In conclusion, fiber laser machines are transforming the landscape of laser technology across various industries. Their exceptional precision, speed, and efficiency make them indispensable tools for metal cutting, welding, engraving, and marking applications. As fiber laser technology continues to evolve, we can expect even more advancements and innovations in the near future. By embracing fiber laser machines, businesses can stay ahead of the competition and unlock new possibilities in manufacturing and beyond.