Introduction: What is cnc pcb milling?

CNC PCB milling is a computer numerical control (CNC) technique used in the manufacturing of printed circuit boards (PCBs). This cutting-edge technology uses automated milling machines to carve out PCBs from copper-clad laminates, offering high precision, efficiency, and accuracy. CNC PCB milling is slowly replacing traditional etching processes, and it has significant benefits, including speed, cost-savings, and design flexibility.

The History of PCB Manufacturing

The history of PCB manufacturing dates back to the early 20th century. During the Second World War, PCBs gained prominence as a vital electronic component, and their demand skyrocketed. Initially, PCBs were made using manual etching processes, which were slow and produced low-quality circuit boards. However, with technological advancements, new methods such as photoengraving and laser-based techniques were introduced, leading to higher quality PCBs. Nevertheless, the introduction of CNC PCB milling has revolutionized the manufacturing industry, offering high-end capabilities for creating complex boards with minimal errors.

The Advantages of CNC PCB Milling

CNC PCB milling has numerous benefits over traditional etching processes. Firstly, it allows for the creation of intricate circuit designs that would be impossible to achieve using manual processes. Secondly, it produces precise and accurate board designs, thereby reducing errors during the manufacturing process. Thirdly, CNC PCB milling reduces the cost of manufacturing PCBs by eliminating the need for costly materials used in the etching process and reducing waste. Finally, it gives designers the flexibility to modify and optimize designs quickly before production.

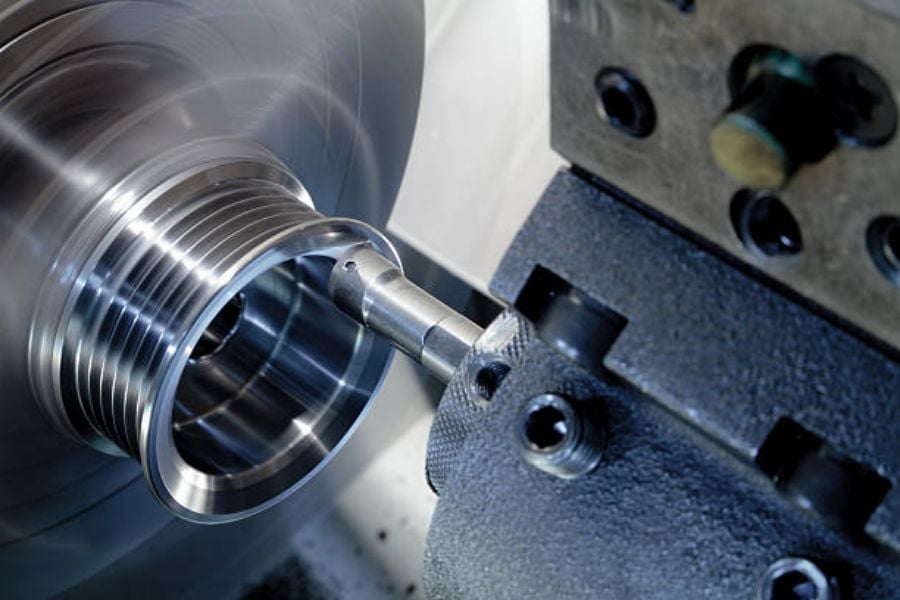

The CNC PCB Milling Process

The CNC PCB milling process involves preparing the design file, selecting the appropriate milling machine, setting up the milling parameters, and executing the milling job. The first step is to prepare the PCB design file using computer-aided design (CAD) software. Next, the milling machine is set up as per the PCB design requirements. The machine executes the milling job by etching away the copper-clad laminate following the design, leaving the desired copper traces and pads. Finally, the finished board undergoes quality checks to ensure that it meets the required specifications.

The Future of PCB Manufacturing

CNC PCB milling is transforming the PCB manufacturing industry. The technology provides high-quality circuit boards with intricate designs, thereby reducing errors, cost, and lead time. The future of PCB manufacturing is driven by the need for miniaturization of electronic devices, and CNC PCB milling is a vital component. The technology is instrumental in creating small, complex, and high-density boards that are popular in devices such as smartphones, drones, and wearable technologies.

The Importance of Choosing the Right Milling Machine

Choosing the right milling machine is vital to the CNC PCB milling process. With various milling machines available in the market, the selection depends on several factors such as precision, speed, durability, and functionality. The ideal machine should have high accuracy, speed, and repeatability to produce intricate designs. Equally important is the software used in controlling the milling machine. Therefore, it is crucial to choose a machine that offers flexibility and compatibility with multiple software.

CNC PCB Milling Vs. Traditional Etching

The traditional etching process has several disadvantages compared to CNC PCB milling. Firstly, the process is time-consuming and labor-intensive, which leads to increased production costs. Secondly, it produces a significant amount of toxic waste, which is not environmentally friendly. Thirdly, the chemical processes employed in traditional etching are not precise and often lead to errors during production. In contrast, CNC PCB milling offers speed, precision, and eliminates the need for toxic chemicals, making it more cost-effective and environmentally friendly.

The Role of CNC PCB Milling in Prototyping

Prototyping is an essential activity in product development. It allows designers to test their ideas, refine designs, and identify potential problems before mass production. CNC PCB milling is instrumental in the prototyping process as it enables quick production of small, complex, and high-quality boards with minimal errors. With the flexibility offered by CNC PCB milling, designers can make changes to their designs quickly, and using the same milling machine, produce several iterations of prototypes for testing.

CNC PCB Milling and Industry 4.0

CNC PCB milling is one of the key technological advancements of Industry 4.0. It provides high precision, speed, and flexibility in manufacturing PCBs, thereby allowing companies to realize mass customization, reduce production costs, and improve efficiency. With the integration of CNC PCB milling with other Industry 4.0 technologies such as the internet of things (IoT), artificial intelligence (AI), and cloud computing, the PCB manufacturing industry will see significant changes in the coming years.

The Future of CNC PCB Milling

As technological advancements continue to drive innovation in the PCB manufacturing industry, CNC PCB milling will remain an essential process in producing high-quality circuit boards. With improvements in milling machines, software, and materials, precision and speed will improve, and costs will reduce further. The future of CNC PCB milling is promising, and as its applications continue to grow, it will continue to shape the future of the electronics industry.