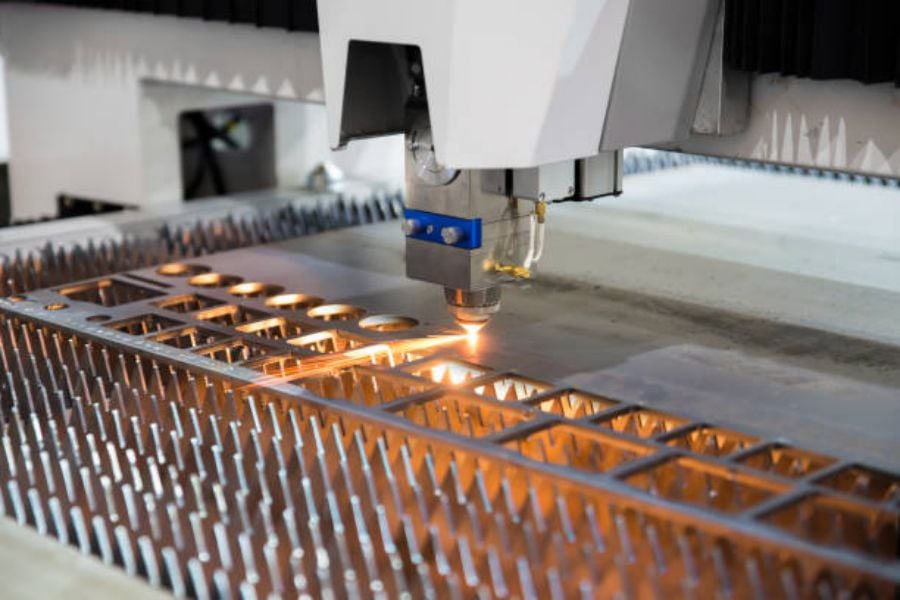

cnc machine manufacturer: An Introduction

A CNC (Computer Numerical Control) machine is a computer-controlled machine tool used for manufacturing different types of products. It can range from simple lathes and mills to advanced 5-axis machining centers. CNC machine manufacturers are companies that design, develop and manufacture these machines. In today's tough competition, choosing the right CNC machine manufacturer is crucial for businesses to stay ahead of the curve. In this article, we will take a closer look at the different factors to consider when selecting the right CNC machine manufacturer for your business.

1. Quality of the Machines

One of the most crucial factors to consider when selecting a CNC machine manufacturer is the quality of their machines. Look for manufacturers who use high-quality materials in the construction of their machines and have strict quality control measures in place during the production process. High-quality machines ensure better performance, improved accuracy, and longer machine life.

2. Range of Products Available

Another important factor to consider is the range of products offered by the CNC machine manufacturer. A manufacturer with a broad portfolio of machines and accessories will offer greater flexibility and versatility to businesses. This will enable them to cater to different industries and meet customized demands of their clients.

3. Innovation and Technology

Technology advancements are happening fast, and the manufacturing industry is not behind. Look for CNC machine manufacturers who invest in research and development to improve the performance of the machines. Manufacturers who offer innovative technology will enable businesses to stay at the forefront of industry changes and gain a competitive edge.

4. Customer Service and Support

The level of customer service and support offered by a CNC machine manufacturer can make or break a business's relationship with them. Good customer service and support are essential to ensure that the equipment runs smoothly with minimal downtime. Ensure that the manufacturer provides prompt assistance to clients and has a dedicated team of engineers available for installation, maintenance and repair services.

5. Training and Skill Development

Buying a CNC machine is just the start. Businesses need skilled operators who can use the machine efficiently and optimize its capabilities. Look for manufacturers who offer training and skill development programs for the machine operators. This will help businesses to get the most out of their machines and increase productivity.

6. Compatibility with Other Systems

CNC machines are complex equipment that requires seamless integration with other systems in the production line. Ensure that the CNC machine manufacturer provides machines that are compatible with other systems used in the business's production line to avoid compatibility issues and costly production delays.

7. Cost and Value

The cost of a CNC machine is undoubtedly an important factor for businesses. However, it should not be the sole deciding factor. Look for manufacturers who provide machines with a good balance of cost and value. Consider the machine's life cycle cost, including factors such as maintenance, repair, and replacement costs. In the long run, investing in a high-quality, durable CNC machine will provide better value for money.

8. Reputation in the Industry

A manufacturer's reputation in the industry speaks volumes about their products and services. Look for CNC machine manufacturers who have proven track records of delivering high-quality machines and excellent customer service and support. Check customer reviews, ratings and feedback to gauge their reputation in the industry.

9. After-Sales Support

After-sales support is crucial to ensure smooth operations of the CNC machine. Look for manufacturers who offer comprehensive after-sales support, including spare parts, technical assistance, and repair and maintenance services. Ensure that the manufacturer provides these services promptly and efficiently to ensure minimal downtime.

10. Customization Options

Every business has unique requirements, and the CNC machine manufacturer should be able to cater to these needs. Look for manufacturers who offer customization options such as modification of software, hardware and machine configuration to meet the specific needs of the business.

Conclusion

Selecting the right CNC machine manufacturer requires careful consideration of several factors, including quality of machines, range of products, innovation and technology, customer service and support, training and skill development, compatibility with other systems, cost and value, reputation in the industry, after-sales support, and customization options. By selecting a reliable and trustworthy CNC machine manufacturer, businesses can ensure maximum productivity, profitability, and success.