Introduction: Understanding cnc engraving machines

CNC engraving machines have revolutionized the world of intricate and precise engraving. These advanced machines utilize computer numerical control (CNC) technology to create detailed designs on various materials such as wood, metal, plastic, and more. In this comprehensive guide, we will explore the different aspects of CNC engraving machines, from their working principles to their applications and benefits.

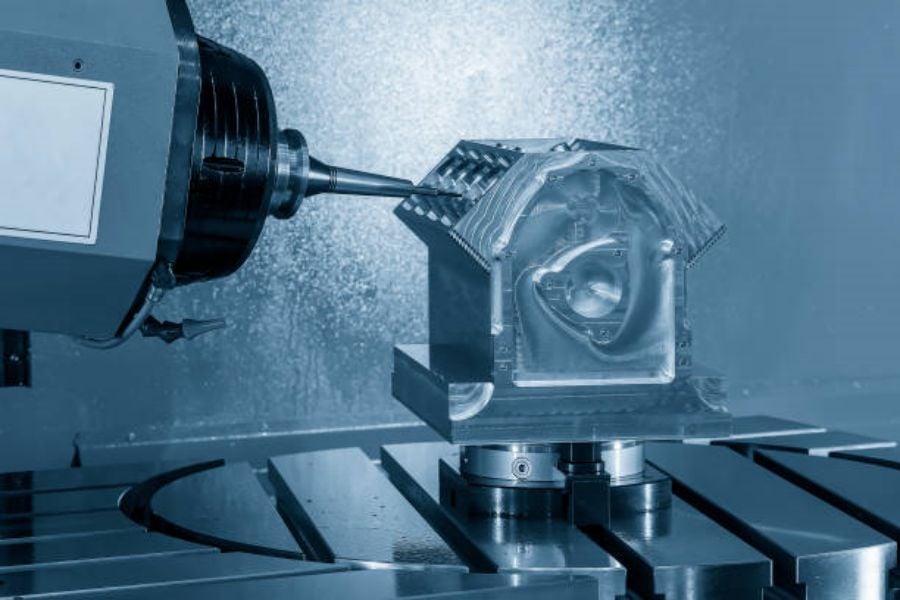

1. How CNC Engraving Machines Work

CNC engraving machines work by following a set of programmed instructions to carve or etch designs onto a workpiece. These instructions, known as G-code, are generated using computer-aided design (CAD) software. The G-code controls the movement of the machine's cutting tool, allowing it to precisely remove material and create intricate patterns.

2. Types of CNC Engraving Machines

There are various types of CNC engraving machines available in the market, each designed for specific applications. Some common types include:

- Desktop CNC engraving machines: Compact machines suitable for small-scale projects and hobbyists.

- Industrial CNC engraving machines: Heavy-duty machines used for large-scale manufacturing and professional applications.

- Laser engraving machines: Utilize laser technology to engrave designs with exceptional precision.

- Rotary engraving machines: Ideal for engraving cylindrical objects such as pens, bottles, and jewelry.

3. Applications of CNC Engraving Machines

CNC engraving machines find applications in a wide range of industries, including:

- Signage and branding: Creating high-quality, custom-designed signs and logos.

- Jewelry making: Engraving intricate patterns and designs on rings, pendants, and bracelets.

- Woodworking: Adding decorative patterns and text to wooden furniture, cabinets, and sculptures.

- Metal fabrication: Engraving serial numbers, logos, and designs on metal parts and components.

- Trophy and award manufacturing: Personalizing trophies and awards with names and achievements.

4. Benefits of Using CNC Engraving Machines

CNC engraving machines offer numerous advantages over traditional engraving methods. Some key benefits include:

- Precision: CNC technology ensures consistent and accurate engraving, even for intricate designs.

- Efficiency: These machines can complete complex engravings in a fraction of the time required by manual methods.

- Versatility: CNC engraving machines can work with a wide range of materials, allowing for diverse applications.

- Automation: Once programmed, the machine can run autonomously, freeing up time for other tasks.

- Cost-effectiveness: CNC engraving reduces labor costs and minimizes material wastage, making it a cost-effective solution.

5. Factors to Consider When Choosing a CNC Engraving Machine

Before investing in a CNC engraving machine, it is essential to consider the following factors:

- Machine size and capacity: Choose a machine that can accommodate your workpiece size and material.

- Spindle power: Higher spindle power allows for faster and deeper engraving.

- Software compatibility: Ensure that the machine is compatible with the CAD software you intend to use.

- Budget: Determine your budget and look for machines that offer the best value for your investment.

6. Maintenance and Care for CNC Engraving Machines

To ensure optimal performance and longevity of your CNC engraving machine, regular maintenance is crucial. Here are some maintenance tips:

- Clean the machine regularly to remove dust and debris.

- Lubricate moving parts to reduce friction and prevent wear.

- Check and tighten any loose bolts or screws.

- Calibrate the machine periodically to maintain accuracy.

- Follow manufacturer guidelines for specific maintenance tasks.

7. Safety Considerations for CNC Engraving Machines

Working with CNC engraving machines involves potential hazards. Follow these safety precautions:

- Wear appropriate protective gear, including safety glasses and gloves.

- Ensure proper ventilation when working with certain materials, such as plastics.

- Secure the workpiece properly to prevent movement during engraving.

- Keep hands and loose clothing away from moving parts.

- Turn off the machine when not in use and disconnect the power source.

8. Training and Skill Development

While CNC engraving machines offer automation, it is important to have the necessary skills to operate and program them effectively. Consider attending training programs or online courses to enhance your understanding of CNC technology and engraving techniques.

9. Future Trends in CNC Engraving Machines

The field of CNC engraving machines is continuously evolving. Some future trends to watch out for include:

- Enhanced automation and artificial intelligence integration.

- Improved precision and faster engraving speeds.

- Integration with 3D scanning and modeling technologies.

- More eco-friendly and sustainable manufacturing processes.

10. Conclusion: Embracing CNC Engraving Machines

CNC engraving machines have revolutionized the art of engraving, offering unparalleled precision, efficiency, and versatility. Whether you are a hobbyist, a small business owner, or part of a large manufacturing unit, investing in a CNC engraving machine can unlock endless creative opportunities and streamline your production processes.