The Advantages of a 4x4 cnc plasma table for Your Metal Fabrication Needs

When it comes to metal fabrication, precision, efficiency, and versatility are key factors for success. A 4x4 CNC plasma table offers all these benefits and more. With its automated cutting capabilities and compact size, this equipment has become a popular choice among metalworkers. In this article, we will explore the various aspects of a 4x4 CNC plasma table and how it can revolutionize your metal fabrication process.

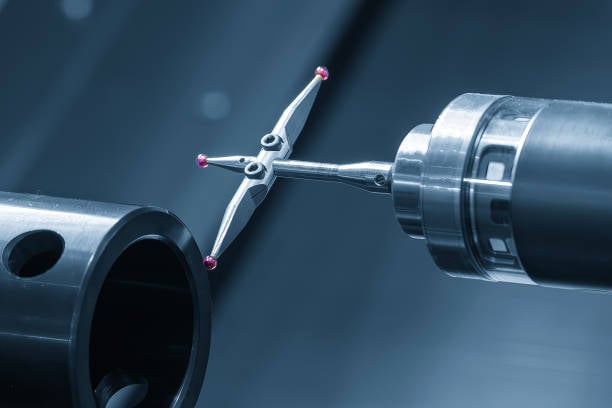

Unleashing Precision with CNC Technology

One of the standout features of a 4x4 CNC plasma table is its use of computer numerical control (CNC) technology. This technology allows for precise and accurate cuts, ensuring that each piece is crafted with the utmost precision. By using computer software to control the movement of the plasma torch, the table can follow intricate designs and cutouts with ease. This precision translates into clean edges and a higher quality finished product, saving both time and material.

Efficiency and Speed in Metal Cutting

Traditional metal cutting methods can be time-consuming and labor-intensive. However, a 4x4 CNC plasma table brings efficiency and speed to the metal cutting process. With its automated system, it can rapidly cut through various types and thicknesses of metal, reducing overall production time. This increased efficiency allows metal fabricators to take on larger projects and meet tight deadlines without compromising on quality.

Versatility for Various Materials and Thicknesses

A 4x4 CNC plasma table is not limited to a specific type or thickness of metal. Whether you work with stainless steel, aluminum, or even non-ferrous metals, this versatile machine can handle them all. By adjusting the power settings and speed of the plasma torch, you can achieve precise cuts regardless of the material's thickness. This adaptability makes a 4x4 CNC plasma table an excellent choice for metal fabricators who work with a wide range of materials.

Precision Cutting with Minimal Waste

Traditional metal cutting methods often result in a significant amount of wasted material due to imprecise cuts and errors. However, a 4x4 CNC plasma table minimizes waste by precisely following the designated cutting path. This accuracy not only saves money on material costs but also reduces the environmental impact of metal fabrication. With a 4x4 CNC plasma table, you can optimize your production process by minimizing waste and maximizing output.

Enhanced Safety Features

Metal fabrication can be a hazardous process, but a 4x4 CNC plasma table comes equipped with various safety features to protect operators and prevent accidents. These safety features include protective enclosures, emergency stop buttons, and automatic shutdown systems. By investing in a 4x4 CNC plasma table, you can ensure a safer working environment for your employees and reduce the risk of workplace injuries.

Improved Workflow and Productivity

With the ability to automate the cutting process, a 4x4 CNC plasma table significantly improves workflow and productivity. The operator can focus on other tasks while the machine works tirelessly to cut through the metal with precision. This automation reduces the reliance on manual labor and allows your workforce to engage in more value-added activities, such as design and quality control. By streamlining your metal fabrication process, you can enhance overall productivity and ultimately boost your bottom line.

Compact Size, Big Results

A 4x4 CNC plasma table offers a compact size without compromising on performance. Its smaller footprint makes it suitable for limited workspace environments, such as small workshops or garages. Despite its size, this machine delivers big results by providing accurate cuts and efficient production. Whether you are a small-scale metal fabricator or a larger operation looking to optimize floor space, a 4x4 CNC plasma table offers the ideal balance between size and functionality.

Cost-Effective Solution for Metal Fabrication

Investing in a 4x4 CNC plasma table is a cost-effective solution for metal fabricators of all sizes. With its automated cutting capabilities and versatility, this machine eliminates the need for manual labor and multiple cutting tools, reducing labor costs and equipment expenses. Additionally, its precision cutting minimizes material waste, leading to further cost savings. Over time, the efficiency and cost-effectiveness of a 4x4 CNC plasma table will undoubtedly make a positive impact on your bottom line.

Increased Design Freedom

Traditional metal cutting methods often limit the complexity and intricacy of designs due to their manual nature. However, a 4x4 CNC plasma table allows for increased design freedom. By importing digital designs into the CNC software, you can create intricate patterns, detailed cutouts, and even replicate complex shapes consistently. Whether you are working on architectural elements, decorative pieces, or industrial components, a 4x4 CNC plasma table unlocks new possibilities for your designs.

Conclusion

A 4x4 CNC plasma table offers a multitude of benefits for metal fabricators, from precision cutting and efficiency to versatility and increased design freedom. With its combination of CNC technology, automation, and safety features, this machine enhances both productivity and profitability. Whether you are a small business owner or a larger operation, investing in a 4x4 CNC plasma table can revolutionize your metal fabrication process, allowing you to meet deadlines, reduce waste, and deliver high-quality products to your customers.